Page 1 of 1

CRAP

Posted: Tue Feb 27, 2007 9:22 pm

by tmbg

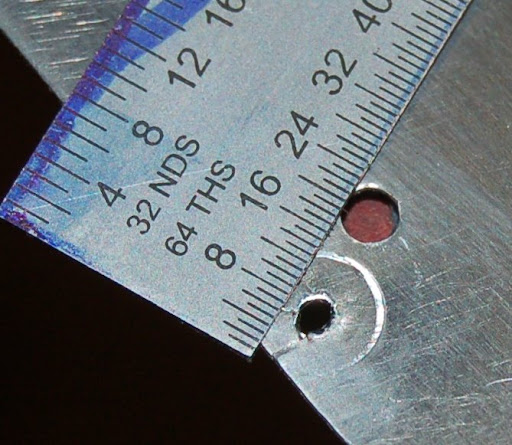

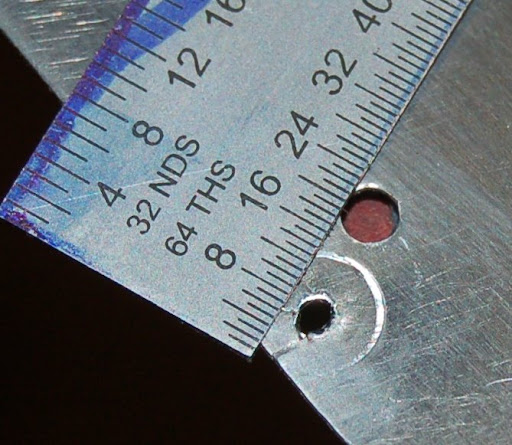

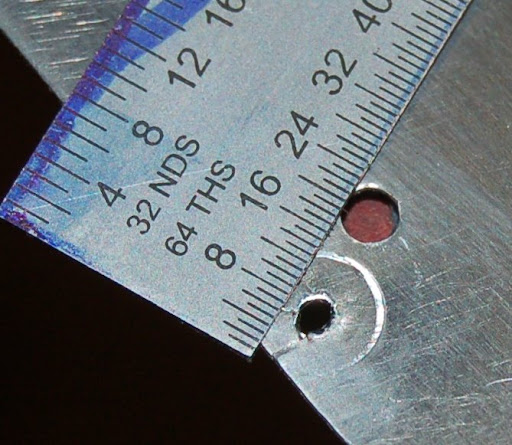

I had a helper over here, helping me get the rudder done, and I was letting him dimple the skins, and he got a bit overzealous with the squeezer, and put an extra hole in it.

Bad enough, right, but it's in the WORST possible spot! The rudder TE

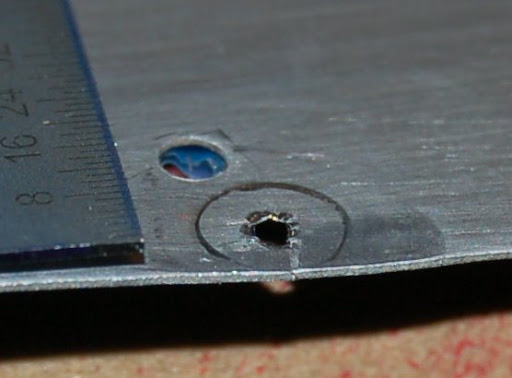

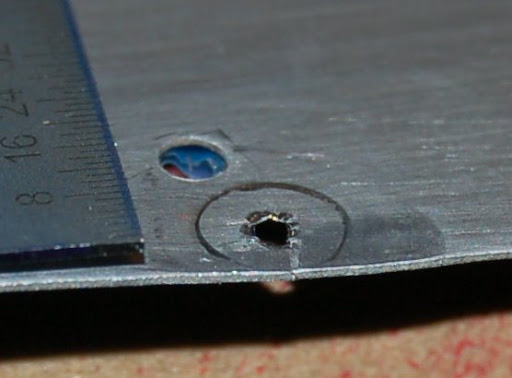

I smashed it back flat with a flat squeezer set... it's cracked across to the TE, but the crack ends in the hole, so I guess it's stop-drilled for me!

What do you folks think... will it fly? Is there something better I can do to repair it? Will the proseal hold it just fine? Or, am I ordering a rudder skin :/

Posted: Tue Feb 27, 2007 9:28 pm

by captain_john

Ian, sorry to jinx you in the other thread where we were talking about just this potential thing happening!

When the pix show, I will give you my $0.02.

CJ

Posted: Tue Feb 27, 2007 10:16 pm

by tshort

I can get the pics by right clicking and choosing "view image" ... but I'm not sure what I'm looking at. Is the larger hole the hole you drilled and the smaller one the error?

I bet a single skin is not too expensive...

Thomas

Posted: Tue Feb 27, 2007 10:25 pm

by tmbg

yeah, the larger hole is the standard hole in the trailing edge, the smaller one is accidental. Here's another pic that puts it more in perspective:

Posted: Tue Feb 27, 2007 10:28 pm

by tmbg

the skin is $40, the stiffeners are $5.50 (I'm guessing that R-915 comes as a bundle, as it was inventoried in the kit), and the shipping will probably be $100.

Ah, the first mistake...

Posted: Tue Feb 27, 2007 10:34 pm

by smithhb

I remember mine well.

Ian, although I think it would be fine after sealing the TE with T-88 or proseal, your "peace of mind" is a greater factor. Go ahead and order the replacement parts and don't look back. BTW, the shipping will be MUCH less than $100 (unless you live in Antarctica!

Posted: Tue Feb 27, 2007 10:49 pm

by Wicked Stick

If I'm under the correct assumption in that your particular rudder is the type where there is no bend line and it just has two trailing edges that are joined together with a piece of aluminum in between and then double flush riveted, I see no reason to get a new skin.

I'd wager it would be fine if you drilled the unwanted dimple hole to a nice clean round hole, deburrend it, and then filled it in with proseal when you sandwhich the parts together and double flush rivet them.

I wee bit of filler before painting and no one would be the wiser.

I wouldn't think it would cause an issue down the road as it's on a flat surface up against the rear insert piece that is prosealed and riveted.

Of course, it is your call on if you want to live with it or not.. The new parts aren't a huge cost.

Posted: Tue Feb 27, 2007 11:54 pm

by cjensen

I TOTALLY agree with Dave here. Unless you just want a new skin to go it again, I'd move on. This is an area that is not going to shift at all when done. Rivet, sealant, AEX wedge. It ain't a show stopper. Really up to you, but it's not gonna fall outta the sky because of it.

Posted: Wed Feb 28, 2007 10:45 am

by Womack2005

Build on!

Posted: Wed Feb 28, 2007 10:50 am

by tmbg

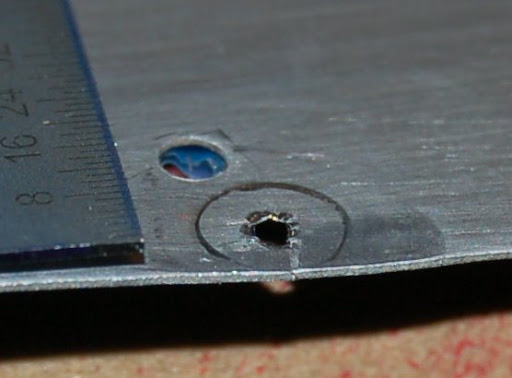

I just spoke to Van's, they said no problem, just drill it to clean it up and notch the edge of the skin where the crack is, so I end up with a little half-moon shape taken out of the edge, then fill it later. Also, he said that if the adjacent rivet no longer meets the edge distance minimum (which it looks like it won't), put another rivet 1/4" or so on the other side, which I can do.

Also, those stiffeners are $5.50 apiece (one piece makes 2), so I'd need like $22 worth of stiffeners in addition to the $40 skin.

Posted: Thu Mar 01, 2007 1:45 pm

by tmbg

and here she is:

Posted: Thu Mar 01, 2007 2:20 pm

by cjensen

That's what I would've done! Good job!

Posted: Thu Mar 01, 2007 5:32 pm

by captain_john

That'll be fine!

CJ